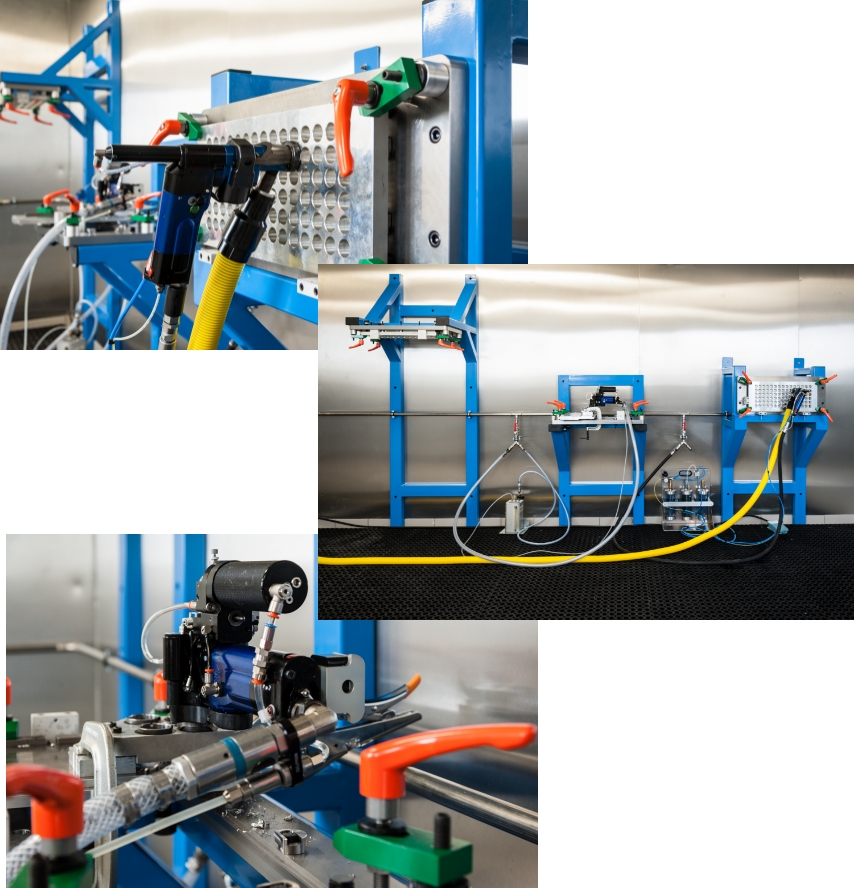

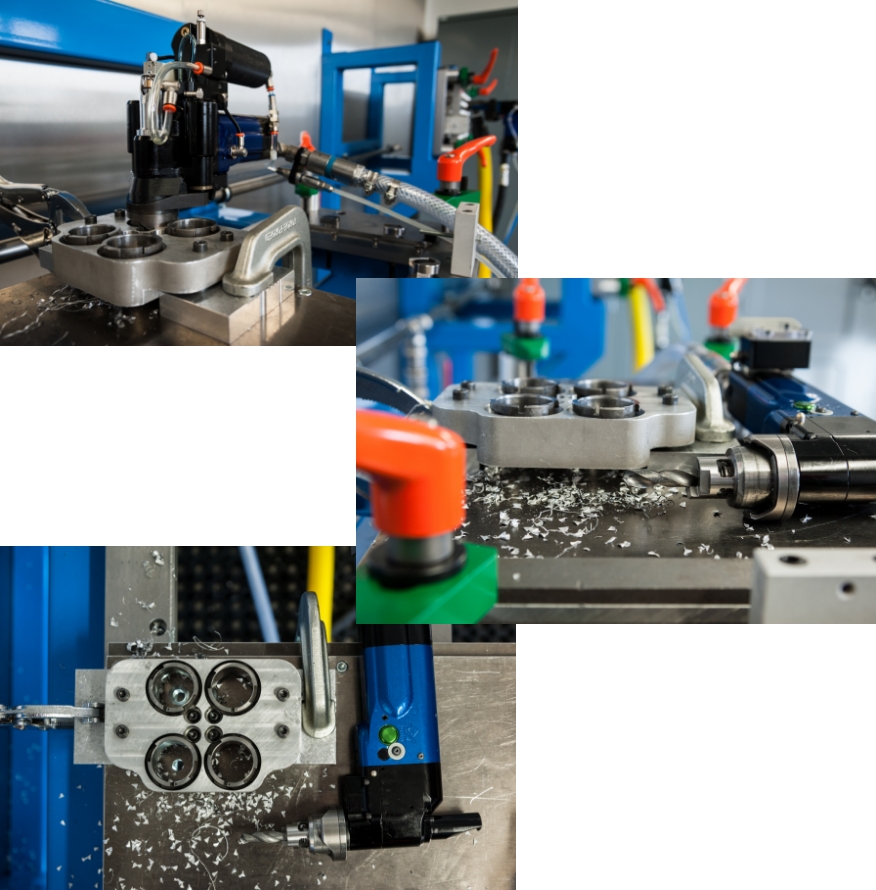

A pneumatic machine ST1200 and an electric machine EDU with different equipment 1⁄4 lathe and concentric collet and spindles(floating or guided spindle).

The pneumatic machine is equipped with the full range of speed and feed.

ST1200 UPA from Seti-Tec, in order to adapt to different types of tools and a Mitis vibration system.

We are also equipped with a flow meter to monitor air consumption during a test, and a portable MQL device with 3 tanks that allow for quick change of lubricant type. This system is fully pneumatic with air and oil flow and pressure control.