Whether manual, semi-manual or CNC, operations on materials as diverse as composites, stacks, NIDA or sandwich panels require considerable experience in tools manufacture, which Nexam embodies.

Whether manual, semi-manual or CNC, operations on materials as diverse as composites, stacks, NIDA or sandwich panels require considerable experience in tools manufacture, which Nexam embodies.

Nexam designs and manufactures a range of hogger plain shank for composite machining to meet your most precise applications.

Our range includes:

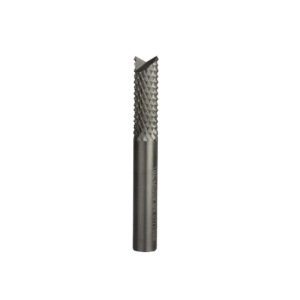

FIBERGLASS ROUTER, carbide, straight cut, from Ø6 to Ø12.7mm. Available in several versions: with or without and cut ,and , drill end and fishtail end cutter. Routing on manual or CNC machines.

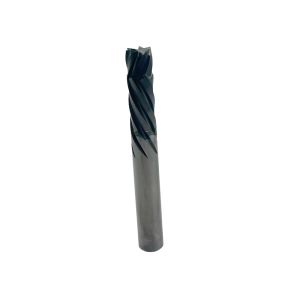

–Alternating helix routers, carbide with or without diamond coating, right hand cut, from Ø6 to Ø12.7mm. Available in several versions: kevlar drill end and 2 size cutter style. Routing on a CNC machine, the alternating helixes allow the cutting edges to be opposed in one turn of the tool and thus avoid any delamination.

Multi- composite hogger plain shank, carbide with or without diamond coating, right or left hand helix, variable number of flute, from Ø3 to Ø12.7mm. A multi-purpose milling cutter, a very good compromise in terms of quality, performance and life, ideal for heavy material removal.

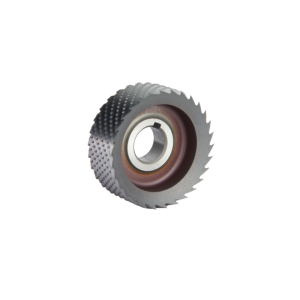

– Composite router, diamond-coated carbide, right or left hand helix, variable tooth count, from Ø3 to Ø12.7mm. Very high performance milling cutter for routing composite materials, reduces cutting efforts but may require a finishing operation. Ideal for large material removal.

– Composite chevron cutter, diamond coated carbide, chevron helix, available in 2 tooth or multi-tooth, from Ø3 to Ø12.7mm. A milling cutter that provides an excellent surface finish. Avoids uncut fibres.

Nexam can make any other types of end mills according to your needs by specifying us your requirements, applications.

Nexam design and manufacture a range of sheet metal machining tools to meet your most precise applications. Our range includes:

– 2 right hand helix routing cutter, HSS or solid carbide, aff hollow sharpening or end drill, available from Ø6 to Ø12.7mm. Routing on manual or CNC machines, the drill bit allows you to start machining without drilling.

-2 left-handed helix router, HSS or solid carbide, hollow sharpening or end milling, available from Ø6 to Ø12.7mm. The left-handed helix directs the efforts towards the end and thus favours the plating of the sheets. The drill tip allows you to start machining without previous drilling, whether you are using a manual or CNC machine.

Nexam can make any other types of end mills according to your needs by specifying us your requirements, applications.

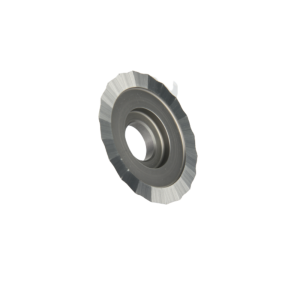

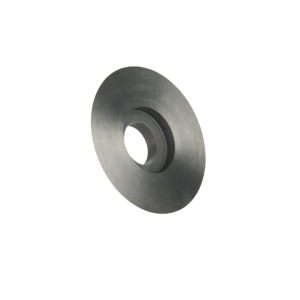

Honeycomb materials have enabled extensive weight savings, especially in industries such as aeronautics and space. However, due to their exceptional characteristics, the machining of these materials is difficult and requires adapted tools.

Depending on its structure, the composite material can be honeycomb (Nomex or Aluminium), laminated or sandwich type, its materiel is also very diversified and can be made of Carbon, Kevlar or even Glass fibre.

The complexity generated by such varied mixtures requires the use of very high-performance tools.

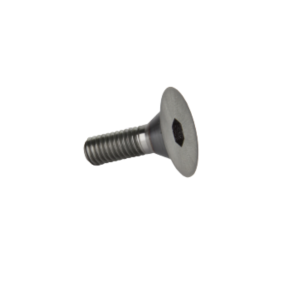

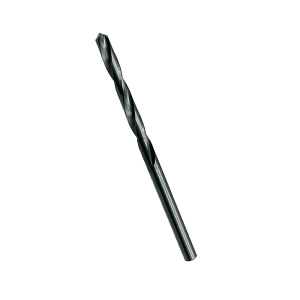

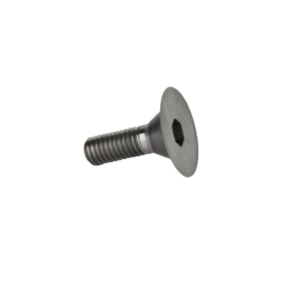

For more than 20 years, Nexam has been designing and manufacturing tools (drill, countersink, reamer…) for pneumatic ADU and electric EDU machines, in high speed steel, carbide and PCD for different types of machine equipment (Concentric collet,

¼ turn, C-clamping…) for drilling/boring your stacks of different types of materials (CFRP, aluminium, Titanium, stainless steels…)

We are able to design the optimal geometry tool to meet your performance and quality objectives / goals, whether it be diameter stability, burr criteria or composite quality.

In order to validate the design we are able to perform in-house tests in our ADU laboratory to assess under production conditions as close as possible to yours, which allows us to secure the start-up of these tools and to offer you a plug&play solution.